16.04.2024, 19:56

16.04.2024, 19:56 Sprache ändern

Sprache ändern

Registrieren

Registrieren Anmelden

Anmelden

Sie sind nicht angemeldet.

Hi all, I am triyng to create a data source in playground. I have two pumps in series. I want to take the %RPM of Pump1, and run Pump2 %RPM by 'Pump1 %RPM' MINUS 'X value'. Ie if Pump1 is running at 40%, I want Pump2 to match Pump1's RPM, but run at minus 5% relative to it, at 35%, for example. I can create this in Virtual Sensors, but this is not the right place, there is not apparent option to turn this into a data source to set the Pump2 controller by. I am sure this is possible but I doing it wrong! Any help much appreciated. Thanks.

Edit: I suppose there is a way to scale the same data source that the pump is using? Or Limit the power usage of the pump directly? To achieve the same effect?

Edit: I suppose there is a way to scale the same data source that the pump is using? Or Limit the power usage of the pump directly? To achieve the same effect?

Dieser Beitrag wurde bereits 3 mal editiert, zuletzt von »alexkyriak« (19. August 2022, 14:32)

I'm guessing you're trying to avoid resonance from the two pumps running at nearly the same RPM. The easiest way to do this is to manage them on the same controller and just trim the output range for one of them.

For example:

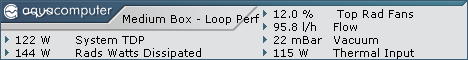

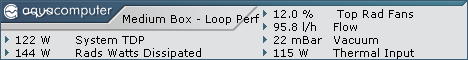

The controller output is scaled across the individual item's range rather than being an absolute value. In this example, a 50% controller output would have Pump 1 running at 50% (halfway between 0 and 100%) and Pump 2 running at 60% (halfway between 20 and 100%). You can trim either the top or bottom of the range. I like to leave the top untouched just in case something unforeseen happens where 100% is required.

For example:

- Pump 1: 0-100%

- Pump 2: 20-100%

The controller output is scaled across the individual item's range rather than being an absolute value. In this example, a 50% controller output would have Pump 1 running at 50% (halfway between 0 and 100%) and Pump 2 running at 60% (halfway between 20 and 100%). You can trim either the top or bottom of the range. I like to leave the top untouched just in case something unforeseen happens where 100% is required.

Edit : Just saw WinstonWoof's answer  so that's my take on your problem using a virtual sensor instead of the offset function :p

so that's my take on your problem using a virtual sensor instead of the offset function :p

As you may have noticed you can't use PWM% as control source for the second pump.

But..

You can still make it work by using temperature units

Create a new virtual sensor in °C and add it to your controller's soft sensors as usual

On your pump 2 header, make a fan curve that goes from 0% at 0°C to 100% at 100°C

Like that, you can still use the numerical value as a PWM percentage.

When your pump 1 runs at 40%, the sensor will generate a 35°C output, that the pump 2 curve will translate into a 35% PWM speed demand

And you'll only have one pump curve to manage, pump 1.

Pump 2 will always reflect the same curve, minus the offset.

so that's my take on your problem using a virtual sensor instead of the offset function :p

so that's my take on your problem using a virtual sensor instead of the offset function :pAs you may have noticed you can't use PWM% as control source for the second pump.

But..

You can still make it work by using temperature units

Create a new virtual sensor in °C and add it to your controller's soft sensors as usual

On your pump 2 header, make a fan curve that goes from 0% at 0°C to 100% at 100°C

Like that, you can still use the numerical value as a PWM percentage.

When your pump 1 runs at 40%, the sensor will generate a 35°C output, that the pump 2 curve will translate into a 35% PWM speed demand

And you'll only have one pump curve to manage, pump 1.

Pump 2 will always reflect the same curve, minus the offset.

Dieser Beitrag wurde bereits 2 mal editiert, zuletzt von »Remayz« (19. August 2022, 01:15)

Guys thank you so much for the comprehensive answers and help, awesome as always, very much appreciated. Two distinct approaches to get to the same solution, will give both a go. Cheers guys

Yes the issue originally stemmed from the combined noise issue when both at same rpm. Am playing with the pumps to understand how they work together. Generally I have the first pump in line running slightly faster than the second but am curious as to how else they could work.

Interestingly whilst I was playing with this originally I running pump 2 at 0rpm as I couldn’t programme the offset, and the system at idle appeared identical to both pumps running, in terms of idle temps and super quiet. Not sure how ‘healthy’ that is for the pump that is on…

The other thing I was looking at was having the second pump kick in at a certain water temperature, same as I have with the fans. Or, have it speed up as the water temperature increases. For this I’d in theory use some other function to make second pump get closer to the first as water temps rise. Theory: one pump and one fan / rad bank working in silent WFH mode, then both pumps and all fans running in game or stress test mode.

Yes the issue originally stemmed from the combined noise issue when both at same rpm. Am playing with the pumps to understand how they work together. Generally I have the first pump in line running slightly faster than the second but am curious as to how else they could work.

Interestingly whilst I was playing with this originally I running pump 2 at 0rpm as I couldn’t programme the offset, and the system at idle appeared identical to both pumps running, in terms of idle temps and super quiet. Not sure how ‘healthy’ that is for the pump that is on…

The other thing I was looking at was having the second pump kick in at a certain water temperature, same as I have with the fans. Or, have it speed up as the water temperature increases. For this I’d in theory use some other function to make second pump get closer to the first as water temps rise. Theory: one pump and one fan / rad bank working in silent WFH mode, then both pumps and all fans running in game or stress test mode.

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »alexkyriak« (19. August 2022, 11:18)

Guys thank you so much for the comprehensive answers and help, awesome as always, very much appreciated. Two distinct approaches to get to the same solution, will give both a go. Cheers guys :)

Yes the issue originally stemmed from the combined noise issue when both at same rpm. Am playing with the pumps to understand how they work together. Generally I have the first pump in line running slightly faster than the second but am curious as to how else they could work.

Interestingly whilst I was playing with this originally I running pump 2 at 0rpm as I couldn’t programme the offset, and the system at idle appeared identical to both pumps running, in terms of idle temps and super quiet. Not sure how ‘healthy’ that is for the pump that is on…

The other thing I was looking at was having the second pump kick in at a certain water temperature, same as I have with the fans. Or, have it speed up as the water temperature increases. For this I’d in theory use some other function to make second pump get closer to the first as water temps rise. Theory: one pump and one fan / rad bank working in silent WFH mode, then both pumps and all fans running in game or stress test mode.

Question

Are you running the pumps in series for a reason ? Eg to increase head pressure?

FOr resiliency purposes wouldn't they be better in parallel (and increasing flow rate) ?

Hi yes I have a ‘relatively’ restrictive loop: 1x360 65mm, 1x360 45mm, 1x360 30mm, cpu block, front and back gpu blocks, a vertical reservoir plate, and lots of 90 degree fittings. There are setups a lot more restrictive than mine I guess and no doubt people will happily run those off a single pump.

But I wanted to keep pressure up and pumps at lower speed. I have no prior experience to back up this decision and it was based on researching the topic on the internet prior to designing and building my system. If you read articles like this (there are lots of others) it gives a good explanation: https://martinsliquidlab.wordpress.com/2…es-vs-parallel/

However now I am running it, aside from the dual pump at same frequency issue, I am experimenting with the characteristics of it. I have not yet been able to calibrate the flow meters on the pump, hope to do that soon, but should have put an actual flow meter in my loop from the off

But I wanted to keep pressure up and pumps at lower speed. I have no prior experience to back up this decision and it was based on researching the topic on the internet prior to designing and building my system. If you read articles like this (there are lots of others) it gives a good explanation: https://martinsliquidlab.wordpress.com/2…es-vs-parallel/

However now I am running it, aside from the dual pump at same frequency issue, I am experimenting with the characteristics of it. I have not yet been able to calibrate the flow meters on the pump, hope to do that soon, but should have put an actual flow meter in my loop from the off

Dieser Beitrag wurde bereits 5 mal editiert, zuletzt von »alexkyriak« (19. August 2022, 14:38)

hehe it's like a wartime stock of 90° fittings :p I have no doubt if you start bending tubes to replace them you'll definitely be able to drop a pump

The components themselves don't look that restrictive, but all those 90s will definitely limit the max flow.

Not long ago i removed a 3x90° run on my pump intake to replace with a 2x45° and gained 20L/h, just with that. kind of gives an idea

Still, a single pump is definitely enough imo

(and if you want to keep the speed low, there's still the DDC option. They vibrate less than D5, have slightly less max RPM but higher head pressure at the same speeds.. so you can run them slower for the same flow, maybe worth a shot in the future if you feel the need to experiment)

The components themselves don't look that restrictive, but all those 90s will definitely limit the max flow.

Not long ago i removed a 3x90° run on my pump intake to replace with a 2x45° and gained 20L/h, just with that. kind of gives an idea

Still, a single pump is definitely enough imo

(and if you want to keep the speed low, there's still the DDC option. They vibrate less than D5, have slightly less max RPM but higher head pressure at the same speeds.. so you can run them slower for the same flow, maybe worth a shot in the future if you feel the need to experiment)

Haha thanks Remayz feeling like such a noob now  I went for 90s for a clean run obviously, I was building wondering exactly that: ‘how much more restriction is this adding’ but then had read that it’s not such an issue if there’s decent flow. ‘Water is water’ was a thing I’d read quite frequently. But knowing I was going to go to two pumps on the basis I had quite a few components I was guessing 90s would be a non issue.

I went for 90s for a clean run obviously, I was building wondering exactly that: ‘how much more restriction is this adding’ but then had read that it’s not such an issue if there’s decent flow. ‘Water is water’ was a thing I’d read quite frequently. But knowing I was going to go to two pumps on the basis I had quite a few components I was guessing 90s would be a non issue.

Ultimately this line of enquiry - hence the original post which you guys did such a great job on answering - is about seeing how silent I can go, and the loudest elements at ‘work from home / idle / non-gaming’ situations are the pumps, by a country mile. Hence wanting to control the dual frequency, and, to start to profile them to activate as load requires.

Incidentally, I read today on Reddit that stuffing a D5 case internally with blue-tac kills a lot of the vibrations that lead to the noise - anyone know of this?

I went for 90s for a clean run obviously, I was building wondering exactly that: ‘how much more restriction is this adding’ but then had read that it’s not such an issue if there’s decent flow. ‘Water is water’ was a thing I’d read quite frequently. But knowing I was going to go to two pumps on the basis I had quite a few components I was guessing 90s would be a non issue.

I went for 90s for a clean run obviously, I was building wondering exactly that: ‘how much more restriction is this adding’ but then had read that it’s not such an issue if there’s decent flow. ‘Water is water’ was a thing I’d read quite frequently. But knowing I was going to go to two pumps on the basis I had quite a few components I was guessing 90s would be a non issue. Ultimately this line of enquiry - hence the original post which you guys did such a great job on answering - is about seeing how silent I can go, and the loudest elements at ‘work from home / idle / non-gaming’ situations are the pumps, by a country mile. Hence wanting to control the dual frequency, and, to start to profile them to activate as load requires.

Incidentally, I read today on Reddit that stuffing a D5 case internally with blue-tac kills a lot of the vibrations that lead to the noise - anyone know of this?

Looks like a nice clean loop!

Some unsolicited thoughts here:

Some unsolicited thoughts here:

- Remayz is correct that the 90s are probably your primary restriction, especially as flow rate goes up. He's also correct that they look good

- Flow restriction might not be a problem in your loop. You can some basic sense of this by:

- Get some good steady-state load into the system. Honestly, mining is as good as you can get for doing that.

- Set fans and pump to full speed

- Monitor the coolant temp and wait for it to hit a mostly steady temp

- Reduce pump speed to 90/80/70%

- At each stage, see what happens with coolant temp and also GPU component temp. You don't need to know the actual flow rate for this, just the coolant temp and pump speed.

- See how low you can go with the pump before the coolant temp at the pump inlet or GPU component temp rises to an unacceptable level

- Get some good steady-state load into the system. Honestly, mining is as good as you can get for doing that.

- Based on that test, you may find that your loop needs less flow than you thought. This is pretty well aligned with what was noted in the big ExtremeRigs testing which found that going from 0.5gpm to 1.0gpm in most rads gave less than a 10% increase in dissipated heat, and going from 1.0 to 1.5 made an even smaller increase. The one exception is for very thick radiators (especially thick + xflow) where going from 0.5 to 1.0 made a meaningful but not big difference and 1.0 to 1.5 made a small one.

- You're probably going to find that, from a flow perspective, you're good with just one pump. That said, having two means that you can lower speed on both and that will ultimately make them last longer. Then again, two pumps means twice the probability that one will fail.

- Resonance will be impacted by the pump mounting, pump orientation, and the stiffness of the mounting surface. Individual pumps mounted to different components using noise isolating mounts will be the quietest option with potentially zero resonance. Coaxial pumps mounted to a large vertical surface with solid standoffs is probably the loudest possible option.

- If you run a Leakshield, you may need to keep dual pumps turned down pretty low to avoid exceeding the maximum pump pressure it can handle.

- Honestly, I've never found properly mounted D5s to be loud. I have a quad rad 1000D build with two D5 NEXTs which actually goes fanless at idle and I can't hear the pumps when that happens.

The flow reduction test will show the GPU temp rise drastically once the flow is just too low.

You seem to have the same waterblock sandwitch i have, so i guess it will happen around the same flow ~70L/h, which is pretty low. On my rig, it happens somewhere under 40% PWM, yours probably a bit faster..

D5 have noisy regions depending on the model and mounting. Mine was heard mostly around 55%, 66% and anything above 75% (both on tube reservoir, and mounted on an EK FLT pump/res). Maybe you'll find the NEXT have that kind of behavior too. The trick is making a fan curve that avoids those noisy spots, and still provides enough water to cool the blocks. Sometimes you have to speed up to make it more silent which is counterintuitive too.

Bottomline, any flow at or above 100L/h is enough for a single GPU + CPU.

With your thick radiators, I wouldn't worry much, even with that lot of fittings Of course they restrict the flow, but i am fairly certain even with one pump you'd still manage.

Of course they restrict the flow, but i am fairly certain even with one pump you'd still manage.

You seem to have the same waterblock sandwitch i have, so i guess it will happen around the same flow ~70L/h, which is pretty low. On my rig, it happens somewhere under 40% PWM, yours probably a bit faster..

D5 have noisy regions depending on the model and mounting. Mine was heard mostly around 55%, 66% and anything above 75% (both on tube reservoir, and mounted on an EK FLT pump/res). Maybe you'll find the NEXT have that kind of behavior too. The trick is making a fan curve that avoids those noisy spots, and still provides enough water to cool the blocks. Sometimes you have to speed up to make it more silent which is counterintuitive too.

Bottomline, any flow at or above 100L/h is enough for a single GPU + CPU.

With your thick radiators, I wouldn't worry much, even with that lot of fittings

Of course they restrict the flow, but i am fairly certain even with one pump you'd still manage.

Of course they restrict the flow, but i am fairly certain even with one pump you'd still manage. Ähnliche Themen

-

English forum »

English forum »-

Aquasuite X cross sensors not updating

(6. Februar 2022, 21:26)

Aquasuite X cross sensors not updating

(6. Februar 2022, 21:26)

-

English forum »

English forum »-

Virtual Sensors Not Mounting to Quadro "Sensors" Tab

(6. September 2021, 20:37)

Virtual Sensors Not Mounting to Quadro "Sensors" Tab

(6. September 2021, 20:37)

-

English forum »

English forum »-

aquasuite X.23: Always up to date

(16. Juli 2020, 12:53)

aquasuite X.23: Always up to date

(16. Juli 2020, 12:53)

-

English forum »

English forum »-

Minor feature request

(7. August 2018, 16:20)

Minor feature request

(7. August 2018, 16:20)

-