27.04.2024, 17:21

27.04.2024, 17:21 Sprache ändern

Sprache ändern

Registrieren

Registrieren Anmelden

Anmelden

Sie sind nicht angemeldet.

- 1

- 2

It sounds to me as if you want to design your cooling for maximum noise level, my cooling is designed for minimum noise level, hence 4x 420 radiators with very slow fans and a pump setting that is not audible.

I also dislike high water temperatures.

Even if the Playground is fun to play with, I would recommend more radiator surface area.

I also dislike high water temperatures.

Even if the Playground is fun to play with, I would recommend more radiator surface area.

Es gibt keinen Ausweg, den ein Mensch nicht beschreitet, um die tatsächliche Arbeit des Denkens zu vermeiden.

Thomas Alva Edison (1847-1931), amerik. Erfinder

Thomas Alva Edison (1847-1931), amerik. Erfinder

if you have that much at idle (if it is radiators input/output difference) it usually means really REEALLY low water flow.

Zitat

For example i'm working with a Delta of 5C at idle and more than double that under any significant load. Time and future tests on the new system with like 3x the rad space will tell, and ill make the necessary config changes to the controller.

smaller rad surface area shouldn't impact differential that much. In fact with less surface area, you should have smaller differentials because the rads dissipate less energy per pass. So it really looks like a low flow situation.

Usually radiators in parallel is very inefficient, people tend to do blocks in parallel instead to avoid feeding one block's heat in the other (even if it makes little difference). But regardless, with parallel loops you usually have to run higher pump speeds by default to make sure the bits you run in parallel get enough flow. If not, there's often one run that gets most of the flow and the others pretty much linger.

Maybe you can try to "reverse" your PWM control, like, running the pump fairly high, and modulate fan speed instead of runnings fans high and having variable pump speed. Purely because of the heavy use of parallel connections, i think it may yield better results.

But yea, finish the loop first then tweak controls :p

It sounds to me as if you want to design your cooling for maximum noise level, my cooling is designed for minimum noise level, hence 4x 420 radiators with very slow fans and a pump setting that is not audible.

I also dislike high water temperatures.

Unfortunately i'm currently forced too, as the first case I built is just big enough to house a push pull 360mm and all cables internally, but aesthetically displays hardware externally. The next will be able to run fans lower and even shut off fans on the smaller rad. It is still almost silent but that's coming from a non PWM air-cooled build lol. I do have good pump insulation.

if you have that much at idle (if it is radiators input/output difference) it usually means really REEALLY low water flow.

smaller rad surface area shouldn't impact differential that much. In fact with less surface area, you should have smaller differentials because the rads dissipate less energy per pass. So it really looks like a low flow situation.

Usually radiators in parallel is very inefficient, people tend to do blocks in parallel instead to avoid feeding one block's heat in the other (even if it makes little difference). But regardless, with parallel loops you usually have to run higher pump speeds by default to make sure the bits you run in parallel get enough flow. If not, there's often one run that gets most of the flow and the others pretty much linger.

Maybe you can try to "reverse" your PWM control, like, running the pump fairly high, and modulate fan speed instead of runnings fans high and having variable pump speed. Purely because of the heavy use of parallel connections, i think it may yield better results.

But yea, finish the loop first then tweak controls :p

That might be the case, I have about 30+ fittings lol and run the pump at 35% idle. But block temps are perfect at idle. Input/output is ~1-2C. Fans at idle are around 50% to maintain ~5C water delta.

Flow meters aren't installed yet

. Parallel rads while receiving half the flowrate, have equal efficiencies because they are working with the same temp delta, so I will see a great difference increasing fan speed. That's why i'm upping to dual pumps in a series, and carefully splitting the flow to ensure each rad is getting the same. Y splitter and equal length tubing, with flow meters and ball valves just in case. They combine into a common manifold at either end, before going to the blocks, so I shouldn't see different block restrictions affecting the flow. A very high flow rate is the goal. If i have to bump the pump baseline up i'm not opposed. I specifically picked x flow rads because they are single pass, my only other option is aquacomputer's airplex as the coolant passageway is all one large tube, not multiple channels. Basically working to minimizing restrictions everywhere besides the blocks and QDC's.

. Parallel rads while receiving half the flowrate, have equal efficiencies because they are working with the same temp delta, so I will see a great difference increasing fan speed. That's why i'm upping to dual pumps in a series, and carefully splitting the flow to ensure each rad is getting the same. Y splitter and equal length tubing, with flow meters and ball valves just in case. They combine into a common manifold at either end, before going to the blocks, so I shouldn't see different block restrictions affecting the flow. A very high flow rate is the goal. If i have to bump the pump baseline up i'm not opposed. I specifically picked x flow rads because they are single pass, my only other option is aquacomputer's airplex as the coolant passageway is all one large tube, not multiple channels. Basically working to minimizing restrictions everywhere besides the blocks and QDC's.

yea, even for a very free flowing loop, 35% is way too low so what you have now is just not enough flow for the blocks to work properly, which i guess is fine at idle, but the minute any load starts you have to crank up the speed immediately. You'd be better off having a higher base speed instead of stressing the pump electronics with constant acceleration/decelerations.

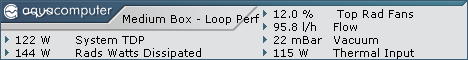

You'll be able to see that well once you have flowmeters installed, but just to give you an idea of the typical values i see at idle, that would be like 0,5 - 0,7°C delta with slow-ish fans around 700 rpm (3x 360 Xflow rads in serie) with a pump at ~55% PWM (about 120L/h here).

if i slow the pump down as slow as it can go, around 36L/h, the delta only climbs to 1,5°C, so i imagine the flow you have right now is uh... extremely small :p

that's with 55W of idle power draw on CPU + GPU, but it may be higher on your rig too.

You'll be able to see that well once you have flowmeters installed, but just to give you an idea of the typical values i see at idle, that would be like 0,5 - 0,7°C delta with slow-ish fans around 700 rpm (3x 360 Xflow rads in serie) with a pump at ~55% PWM (about 120L/h here).

if i slow the pump down as slow as it can go, around 36L/h, the delta only climbs to 1,5°C, so i imagine the flow you have right now is uh... extremely small :p

that's with 55W of idle power draw on CPU + GPU, but it may be higher on your rig too.

@DeathToTheWind

One of your problems is the 8 QDCs, that is a serious bunch of restriction. I have 2, to be able to decouple my external radiator, never any internally.

And placing 2 radiators in parallel is not really an advantage. You get half the flow per radiator, so double time in the radiator, but only one radiator, so it should be about equal.

One of your problems is the 8 QDCs, that is a serious bunch of restriction. I have 2, to be able to decouple my external radiator, never any internally.

And placing 2 radiators in parallel is not really an advantage. You get half the flow per radiator, so double time in the radiator, but only one radiator, so it should be about equal.

Correct which is why im using a dual pump in series so that I can combine the head from both. If I up the flow rate parallel rads will be more efficient. And the pressure drop from the QDC’s and parallel rads will be manageable with the increased pump pressure. Only reason I’m doing 8 is purely so I can exchange all hardware without draining the loop through the fold out MB tray.

Correct which is why im using a dual pump in series so that I can combine the head from both. If I up the flow rate parallel rads will be more efficient. And the pressure drop from the QDC’s and parallel rads will be manageable with the increased pump pressure. Only reason I’m doing 8 is purely so I can exchange all hardware without draining the loop through the fold out MB tray.

I would just give it an actual drain port on the bottom and a "drain port" on the top where you can hook in a LeakSHIELD as needed. With a loop like yours where everything is vertical and plumbed in parallel, a LeakSHIELD can really easily do a vacuum-assisted fill on the first shot without even needing to cycle the pump. Without those QDCs, a single D5 could easily hit 200lph in a loop like yours and that would be well beyond the point of diminishing returns with regard to coolant flow.

You have like 600W max sustained load even with a 4090 in there. This whole loop could be run by a D5 NEXT set to a 40C target and a SPLITTY 9 for connecting the fans. Coolant flow and fan speeds (including turning off completely) would all be automatically regulated.

This is interesting. It kind of reminds me of the Intercooler Thermal Regulator. That did turn out to have some significant issues, but those aside, it was another example of complex sensor data processing that can be done in Aquasuite.

I suspect they are the same person.

I would just give it an actual drain port on the bottom and a "drain port" on the top where you can hook in a LeakSHIELD as needed. With a loop like yours where everything is vertical and plumbed in parallel, a LeakSHIELD can really easily do a vacuum-assisted fill on the first shot without even needing to cycle the pump. Without those QDCs, a single D5 could easily hit 200lph in a loop like yours and that would be well beyond the point of diminishing returns with regard to coolant flow.

You have like 600W max sustained load even with a 4090 in there. This whole loop could be run by a D5 NEXT set to a 40C target and a SPLITTY 9 for connecting the fans. Coolant flow and fan speeds (including turning off completely) would all be automatically regulated.

LeakShield is planed if I can make the standalone version fit on top, that or I will vacuum fill it with either the vacuum pump I have for composites or a compressor attachment with a vacuum regulator. Both vertical side rads have multiple ports on the bottom to drain. Hardest part will be the 92mm rad. Case will have to tilt for that. I want something small that has the workability of a large case, hence the quick disconnects, fold out radiators, and hardware mounts. It's also a personal challenge to improve my CAD skills.

Its controlled off an OCTO and Farbwerk 360 with 2 flow meters and 8 temp sensors. And really with the QDC's its no different then multi GPU systems running in parallel off a manifold.

I suspect they are the same person.

This sensor was created by me, I have nothing to do with the other. It was a theory and its worked great so far. With the latest tweaks to my minimum pump speed, the fans have come down slightly, and the pump still only spools up when absolutely needed.

- 1

- 2

Ähnliche Themen

-

English forum »

English forum »-

Virtual Sensor Temp Spike Upon PC WakeUp

(21. Dezember 2021, 20:31)

Virtual Sensor Temp Spike Upon PC WakeUp

(21. Dezember 2021, 20:31)

-

English forum »

English forum »-

Help on temperature monitoring

(4. Juni 2014, 16:18)

Help on temperature monitoring

(4. Juni 2014, 16:18)

-

English forum »

English forum »-

New to Fan Controllers - purchased Aquaero 6 XT ... not sure what to do from here

(3. April 2014, 17:25)

New to Fan Controllers - purchased Aquaero 6 XT ... not sure what to do from here

(3. April 2014, 17:25)

-

English forum »

English forum »-

Aquasuite - Here are my settings - What are yours ?

(27. Juni 2013, 17:52)

Aquasuite - Here are my settings - What are yours ?

(27. Juni 2013, 17:52)

-

English forum »

English forum »-

Display sensors on one page

(25. Oktober 2012, 14:14)

Display sensors on one page

(25. Oktober 2012, 14:14)

-