18.04.2024, 21:46

18.04.2024, 21:46 Sprache ändern

Sprache ändern

Registrieren

Registrieren Anmelden

Anmelden

Sie sind nicht angemeldet.

Lieber Besucher, herzlich willkommen bei: Aqua Computer Forum. Falls dies Ihr erster Besuch auf dieser Seite ist, lesen Sie sich bitte die Hilfe durch. Dort wird Ihnen die Bedienung dieser Seite näher erläutert. Darüber hinaus sollten Sie sich registrieren, um alle Funktionen dieser Seite nutzen zu können. Benutzen Sie das Registrierungsformular, um sich zu registrieren oder informieren Sie sich ausführlich über den Registrierungsvorgang. Falls Sie sich bereits zu einem früheren Zeitpunkt registriert haben, können Sie sich hier anmelden.

- 1

- 2

Hey all.

I am in the process of building a rather large loop for my Threadripper system, which I am documenting here.

Hey all,

I have had a rather weird issue which I am hoping I might poke your brains with.

This is the build that has had just about everything that can go wrong with it go wrong.

A couple of weeks ago, I thought I was close to finishing the build.

I had done a few flushes and test filled with distilled water. With my dual pump top I was getting great flow values as measured with my Aquaero. With one pump running I was seeing 1.1GPH (~250L/H). With both pumps running that number went up to 1.6 GPM (~365L/H)

I was pretty happy with those numbers.

Then I ran into a problem with my fans. I had bought Noctua iPPC fans, and they were not cooperating with the Aquaero due to this issue. Of course I didn't discover this post on th eforum right away, so I was trouble shooting pulling fan cables, reconnecting trying to figure out what was wrong. At some point in that process I somehow damaged my Aquaero. PWM port 4 was no longer working. (ESD maybe?). So I ordered another one on Amazon. I also ordered a whole new complement of fans from Arctic. Due to essential items shipping first during the pandemic (no complaint from me there, essential items are more important than my hobby) it took a while for them come in, but I finally got them.

I went to install everything today. Everything looked good. Filled it up with my real coolant this time (EK Cryofuel) and started up the new Aquaero and the pumps.

The problem? Now my flow with one pump is reading as anywhere from 0.3GPM to 0.6GPM (~70L/H - 130L/h) and my flow with both is reading anywhere from 0.5 to 1.1GPM (~110L/h - 250L/H) a significant drop from where it was before. It seems to drift lower as time goes on. When I first power it up, starting at about 1.1GPM, but gradually getting lower and lower over time.

A few notes:

1.) Aquasuite did just update to the latest version (x14 to x16 I think based on release dates, but I didn't check what version I was on before). Looks like historical version downloads are not available, so I cannot test with older versions.

2.) Loop configuration and pumps are otherwise exactly the same

3.) Both D5 pumps are running just at about their specs of 4800rpm

Based on the erratic decreasing flow readings, and the fact that everything looked and sounded normal when I filled the system, I am leaning towards that the readings are wrong, and not that the flow has dropped, but I am not sure.

Some theories of what is going on:

a.) New version of Aquasuite software has a bug?

b.) Flowmeter is damaged somehow?

c.) Flow meter wire is bad resulting in poor connection to Aquaero

d.) Air bubble is caught somewhere in the loop or in the flow meter

e.) something has gotten into the loop and is causing an obstruction slowing flow

f.) My coolant is somehow more difficult to push through the loop than pure distilled water? (Seems very unlikely)

g.) Old flow numbers were erroneous and too high?

Troubleshooting I've done so far:

I have confirmed it is not the Aquaero itself which is the problem. The old Aquaero still functions, (just without PWM port 4) and it confirms the same flow readings as the new one.

I have also verified that the calibration is set accurate for my flowmeter ( 53068 )

I was using a 3 pin fan extension cable to help the wiring reach the Aquaero. To eliminate this as the cause, I have tried plugging the Aquacomputer flowmeter cable straight into the aquaero, with no chance in readouts.

Anyway, I'd appreciate any suggestions anyone might have on troubleshooting this issue.

Thanks,

Matt

I am in the process of building a rather large loop for my Threadripper system, which I am documenting here.

Hey all,

I have had a rather weird issue which I am hoping I might poke your brains with.

This is the build that has had just about everything that can go wrong with it go wrong.

A couple of weeks ago, I thought I was close to finishing the build.

I had done a few flushes and test filled with distilled water. With my dual pump top I was getting great flow values as measured with my Aquaero. With one pump running I was seeing 1.1GPH (~250L/H). With both pumps running that number went up to 1.6 GPM (~365L/H)

I was pretty happy with those numbers.

Then I ran into a problem with my fans. I had bought Noctua iPPC fans, and they were not cooperating with the Aquaero due to this issue. Of course I didn't discover this post on th eforum right away, so I was trouble shooting pulling fan cables, reconnecting trying to figure out what was wrong. At some point in that process I somehow damaged my Aquaero. PWM port 4 was no longer working. (ESD maybe?). So I ordered another one on Amazon. I also ordered a whole new complement of fans from Arctic. Due to essential items shipping first during the pandemic (no complaint from me there, essential items are more important than my hobby) it took a while for them come in, but I finally got them.

I went to install everything today. Everything looked good. Filled it up with my real coolant this time (EK Cryofuel) and started up the new Aquaero and the pumps.

The problem? Now my flow with one pump is reading as anywhere from 0.3GPM to 0.6GPM (~70L/H - 130L/h) and my flow with both is reading anywhere from 0.5 to 1.1GPM (~110L/h - 250L/H) a significant drop from where it was before. It seems to drift lower as time goes on. When I first power it up, starting at about 1.1GPM, but gradually getting lower and lower over time.

A few notes:

1.) Aquasuite did just update to the latest version (x14 to x16 I think based on release dates, but I didn't check what version I was on before). Looks like historical version downloads are not available, so I cannot test with older versions.

2.) Loop configuration and pumps are otherwise exactly the same

3.) Both D5 pumps are running just at about their specs of 4800rpm

Based on the erratic decreasing flow readings, and the fact that everything looked and sounded normal when I filled the system, I am leaning towards that the readings are wrong, and not that the flow has dropped, but I am not sure.

Some theories of what is going on:

a.) New version of Aquasuite software has a bug?

b.) Flowmeter is damaged somehow?

c.) Flow meter wire is bad resulting in poor connection to Aquaero

d.) Air bubble is caught somewhere in the loop or in the flow meter

e.) something has gotten into the loop and is causing an obstruction slowing flow

f.) My coolant is somehow more difficult to push through the loop than pure distilled water? (Seems very unlikely)

g.) Old flow numbers were erroneous and too high?

Troubleshooting I've done so far:

I have confirmed it is not the Aquaero itself which is the problem. The old Aquaero still functions, (just without PWM port 4) and it confirms the same flow readings as the new one.

I have also verified that the calibration is set accurate for my flowmeter ( 53068 )

I was using a 3 pin fan extension cable to help the wiring reach the Aquaero. To eliminate this as the cause, I have tried plugging the Aquacomputer flowmeter cable straight into the aquaero, with no chance in readouts.

Anyway, I'd appreciate any suggestions anyone might have on troubleshooting this issue.

Thanks,

Matt

Dieser Beitrag wurde bereits 3 mal editiert, zuletzt von »mattlach« (20. April 2020, 04:18)

f.) My coolant is somehow more difficult to push through the loop than pure distilled water? (Seems very unlikely)

Of course the EK Cryofuel is more difficult to push than distilled water.

It contains Propylene Glycol, which has a higher viscosity than Water.

Well, yes, but what I meant was it seems unlikely like it is the cause in this case.

EK's Cryofuel comes in 100ml bottles intended to be diluted with 900ml of water to make 1L of coolant.

Even if we assume that all of that 100ml is Propylene Glycol, which I don't think it is, we are still talking 90% distilled water, so it seems unlikely it would reduce flow from 1.6 GPM down to 0.6 GPM.

That said, my fluid dynamics are very very rusty (I took one Engineering class on it 20 years ago, and I don't remember the impacts of viscosity on flow at all) so if you are more educated on the subject, I'd appreciate your thoughts on the matter.

Alrighty.

I did some follow up testing with the system assembled and running, and I believe I have confirmed that it is the flowmeter readout that is incorrect, not the actual flow that is diminished.

I loaded up the system with a loop of heaven benchmark at 4k, maximum quality settings, vsync off, on a highly overclocked Pascal Titan X and let it run until the system reached a steady state.

The system was maintaining a temperature delta between the measured coolant temperature at the GPU and the core temperature of the GPU of only between 2 and 4C. If the flow meter readouts were accurate, this should not be possible.

Does anyone have any flowmeter troubleshooting suggestions? Can they be opened up and maintained?

Thanks,

Matt

I did some follow up testing with the system assembled and running, and I believe I have confirmed that it is the flowmeter readout that is incorrect, not the actual flow that is diminished.

I loaded up the system with a loop of heaven benchmark at 4k, maximum quality settings, vsync off, on a highly overclocked Pascal Titan X and let it run until the system reached a steady state.

The system was maintaining a temperature delta between the measured coolant temperature at the GPU and the core temperature of the GPU of only between 2 and 4C. If the flow meter readouts were accurate, this should not be possible.

Does anyone have any flowmeter troubleshooting suggestions? Can they be opened up and maintained?

Thanks,

Matt

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »mattlach« (21. April 2020, 07:59)

Which pumps are you using?

350 L/h is a huge amount. I would say the first was wrong and now the second with more like 130L/h is the right one.

The sensor itself is one of the most reliable and accurate ones on the market. There was a test recently from igors Lab (afraid its german) from this exact sensor against professionel Calibrated Hardware. It is pretty accurate.

https://www.youtube.com/watch?v=hpppg9BUAso

To see some Competitor against it (Spoiler: They suck BIG time)

https://www.youtube.com/watch?v=ovY1epfaQ5Y

350 L/h is a huge amount. I would say the first was wrong and now the second with more like 130L/h is the right one.

From the Handbook. Maybe this is, or was, the problem. Check if the Aquaero uses the right value.

Zitat

Depending on device and software version, the flow sensor input

of the device must either be configured as sensor type “Flow sensor high

flow (5306” or be set to a calibration value of 169 impulses per liter.

The sensor itself is one of the most reliable and accurate ones on the market. There was a test recently from igors Lab (afraid its german) from this exact sensor against professionel Calibrated Hardware. It is pretty accurate.

https://www.youtube.com/watch?v=hpppg9BUAso

To see some Competitor against it (Spoiler: They suck BIG time)

https://www.youtube.com/watch?v=ovY1epfaQ5Y

Adding to this:Alrighty.

I did some follow up testing with the system assembled and running, and I believe I have confirmed that it is the flowmeter readout that is incorrect, not the actual flow that is diminished.

I loaded up the system with a loop of heaven benchmark at 4k, maximum quality settings, vsync off, on a highly overclocked Pascal Titan X and let it run until the system reached a steady state.

The system was maintaining a temperature delta between the measured coolant temperature at the GPU and the core temperature of the GPU of only between 2 and 4C. If the flow meter readouts were accurate, this should not be possible.

Does anyone have any flowmeter troubleshooting suggestions? Can they be opened up and maintained?

Thanks,

Matt

Yes it can be opened and maintained.

As i said before: Its more than unlikely that the sensor itself has a problem. If there would be a problem normally it wouldn´t show any value at all because there is only one moveable piece in it. If that would be stopped or blocked because some particle in the water it would show nothing.. a partcle that just slows it down (and sticks to it) would be very hard to find.

The Temperature Delta is in no way a source of reading your flow. The difference from 50L/h to 250L/h is maybe 2-3K. Only if your flow is less then 40L/h you will see a real effect by enhancing the flow. Effects above that could be easily bee within the error margin of the temperature sensors.

As to the point of viscosity:

10% could make a huge differance.

Interesting article from Crane Engineering

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »InfoSeeker« (21. April 2020, 17:30)

Adding to this:Alrighty.

I did some follow up testing with the system assembled and running, and I believe I have confirmed that it is the flowmeter readout that is incorrect, not the actual flow that is diminished.

I loaded up the system with a loop of heaven benchmark at 4k, maximum quality settings, vsync off, on a highly overclocked Pascal Titan X and let it run until the system reached a steady state.

The system was maintaining a temperature delta between the measured coolant temperature at the GPU and the core temperature of the GPU of only between 2 and 4C. If the flow meter readouts were accurate, this should not be possible.

Does anyone have any flowmeter troubleshooting suggestions? Can they be opened up and maintained?

Thanks,

Matt

Yes it can be opened and maintained.

As i said before: Its more than unlikely that the sensor itself has a problem. If there would be a problem normally it wouldn´t show any value at all because there is only one moveable piece in it. If that would be stopped or blocked because some particle in the water it would show nothing.. a partcle that just slows it down (and sticks to it) would be very hard to find.

The Temperature Delta is in no way a source of reading your flow. The difference from 50L/h to 250L/h is maybe 2-3K. Only if your flow is less then 40L/h you will see a real effect by enhancing the flow. Effects above that could be easily bee within the error margin of the temperature sensors.

As to the point of viscosity:

10% could make a huge differance.

This does not jive with the data I have seen on the subject, or the "rule of thumb" guides on any of the enthusiast water cooling sites out there.

Maybe this is accurate for very low heat systems, but 40 L/H is a laughably inadequate flow rate for an enthusiast system where each block (GPU & CPU) could be dissipating 300W to 350W of heat.

My Pascal Titan X, fully overclocked puts out ~310W at full load. My Threadripper 3960x at full load can get up to 320W at full load.

The rule of thumb in all enthusiast water cooling forums is to target 1 GPM, (~227 L/H), as that is an approximate point where diminishing returns set in to the point where further flow increases may not be worth it. Still, measurable improvements are notable up to about 1.5GPM (340 L/h) after which thermal probe accuracy starts to limit the ability to distinguish probe error and actual temperature improvement.

While the rule of thumb target is ~ 1 GPM (227L/H) generally it is conceded that if you can reach a minimum of 0.8 GPM (~180L/h) you are OK. Not great, but OK.

Usually, unless a loop is large and complex, a single D5 pump running at 100% speed is sufficient to reach ~ 0.8 to 1.1 GPM (180 to 250 L/H)

40 L/H is ~ 0.17 GPM. That might be fine for idle flow rates if you have a PWM pump and can dial it down when temps are low, but for load conditions it is a joke.

For some historical reference.

My old loop ( single D5 pump, EK Fullcover Block for Pascal Titan X, EK Supremacy EVO Block for CPU, 1x 420mm 45mm thick Alphacool Radiator, 1x 280mm "Monsta" 84.5mm thick radiator) achieved about 0.9 GPM (~205 L/H) at full pump speed with EK Cryofuel Coolant

When I upgraded to Threadripper, at first I used the same loop, just replacing the CPU block with a Watercool Heatkiller IV Pro Threadripper block. It was apparently less restrictive than the EK Supremancy EVO, because this change alone increased max flow to 1.1GPM (~250L/h) with EK Cryofuel Coolant

When I embarked on a larger loop for my threadripper with a little bit of an unusual parallel flow radiator routing (see here) I decided to add a second pump to help overcome what I thought would be a more restrictive loop. Initial testing with just distilled water showed a single D5 pump at full speed resulting in 1.1 GPM (~250L/H), and with both pumps up to 1.6 GPM (~360 L/H)

This is why this drop is so puzzling.

I always question people’s flow numbers, I’m running triple D5 pumps in series and using a AQ high flow sensor and with all 3 at max only see 400lph.

Added pumps in series increase head pressure linearly, but flow rate does not increase linearly with head pressure.

This helps explain it. Each pump added to a loop results in less of a gain in flow than the pump before it, and how much depends on the system curve of the loop.

Yes it can be opened and maintained.

As i said before: Its more than unlikely that the sensor itself has a problem. If there would be a problem normally it wouldn´t show any value at all because there is only one moveable piece in it. If that would be stopped or blocked because some particle in the water it would show nothing.. a partcle that just slows it down (and sticks to it) would be very hard to find..

That makes sense. I've never looked inside the sensor. I imagine it is some sort of wheel on an axle that spins with the flow?

Yeah, having particulate stick and slow the wheel down seems unlikely, but maybe something string-like or hair could wrap itself around the axle causing resistance? My work area is reasonably clean, but definitely not a clean room, so some contamination is possible, albeit unlikely.

Either that, or maybe the same ESD damage or whatever damaged my old Aquaero, also harmed the flow sensor?

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »mattlach« (21. April 2020, 18:25)

I did the math right now on a piece of paper, i studied it and i scored top of my class in "heat transfer" class. You can trust a german engineer when he tells you: Yes there is a difference with an increased flow, no it does not dramatically change UNLESS you change the form of the flow from laminar to turbulent and thus reducing the boundary layer (https://en.wikipedia.org/wiki/Boundary_layer). All my calculations (though pretty simplified because there are a huge number of variables) show pretty the same: Unless you are in some real edge cases design wise (which i hardly doubt in watercooling) the flow stays the same wether you have 60L/h or 300L/h.Adding to this:Alrighty.

I did some follow up testing with the system assembled and running, and I believe I have confirmed that it is the flowmeter readout that is incorrect, not the actual flow that is diminished.

I loaded up the system with a loop of heaven benchmark at 4k, maximum quality settings, vsync off, on a highly overclocked Pascal Titan X and let it run until the system reached a steady state.

The system was maintaining a temperature delta between the measured coolant temperature at the GPU and the core temperature of the GPU of only between 2 and 4C. If the flow meter readouts were accurate, this should not be possible.

Does anyone have any flowmeter troubleshooting suggestions? Can they be opened up and maintained?

Thanks,

Matt

Yes it can be opened and maintained.

As i said before: Its more than unlikely that the sensor itself has a problem. If there would be a problem normally it wouldn´t show any value at all because there is only one moveable piece in it. If that would be stopped or blocked because some particle in the water it would show nothing.. a partcle that just slows it down (and sticks to it) would be very hard to find.

The Temperature Delta is in no way a source of reading your flow. The difference from 50L/h to 250L/h is maybe 2-3K. Only if your flow is less then 40L/h you will see a real effect by enhancing the flow. Effects above that could be easily bee within the error margin of the temperature sensors.

As to the point of viscosity:

10% could make a huge differance.

This does not jive with the data I have seen on the subject, or the "rule of thumb" guides on any of the enthusiast water cooling sites out there.

Maybe this is accurate for very low heat systems, but 40 L/H is a laughably inadequate flow rate for an enthusiast system where each block (GPU & CPU) could be dissipating 300W to 350W of heat.

My Pascal Titan X, fully overclocked puts out ~310W at full load. My Threadripper 3960x at full load can get up to 320W at full load.

The rule of thumb in all enthusiast water cooling forums is to target 1 GPM, (~227 L/H), as that is an approximate point where diminishing returns set in to the point where further flow increases may not be worth it. Still, measurable improvements are notable up to about 1.5GPM (340 L/h) after which thermal probe accuracy starts to limit the ability to distinguish probe error and actual temperature improvement.

While the rule of thumb target is ~ 1 GPM (227L/H) generally it is conceded that if you can reach a minimum of 0.8 GPM (~180L/h) you are OK. Not great, but OK.

Usually, unless a loop is large and complex, a single D5 pump running at 100% speed is sufficient to reach ~ 0.8 to 1.1 GPM (180 to 250 L/H)

40 L/H is ~ 0.17 GPM. That might be fine for idle flow rates if you have a PWM pump and can dial it down when temps are low, but for load conditions it is a joke.

For some historical reference.

My old loop ( single D5 pump, EK Fullcover Block for Pascal Titan X, EK Supremacy EVO Block for CPU, 1x 420mm 45mm thick Alphacool Radiator, 1x 280mm "Monsta" 84.5mm thick radiator) achieved about 0.9 GPM (~205 L/H) at full pump speed with EK Cryofuel Coolant

When I upgraded to Threadripper, at first I used the same loop, just replacing the CPU block with a Watercool Heatkiller IV Pro Threadripper block. It was apparently less restrictive than the EK Supremancy EVO, because this change alone increased max flow to 1.1GPM (~250L/h) with EK Cryofuel Coolant

When I embarked on a larger loop for my threadripper with a little bit of an unusual parallel flow radiator routing (see here) I decided to add a second pump to help overcome what I thought would be a more restrictive loop. Initial testing with just distilled water showed a single D5 pump at full speed resulting in 1.1 GPM (~250L/H), and with both pumps up to 1.6 GPM (~360 L/H)

This is why this drop is so puzzling.

Just try it yourself. Switch one pump off (if your flow stays above 40-50 L/h) you will not see a huge difference (like 10K+) in temperatures. For that you need to wait to the point where the water temperature does not change anymore and your system becomes static.

This is somehow a intercontinental difference - you americans tend to always go for high flow, europeans tend to go for sufficient flow but as silent as possible. At least here on the europe side there is a large community who does really good test nearly scientifically based around all aspects. All found that Flow CAN improve your temperatures but only by a margin that is not big enough to bother. Better get another radiator and lower the watertemp from the start.

Edit:

The above is only true for watercooling PCs - if you are trying to cool down steel beams or rolling mills in steel plants its a whole different story because your delta Temperatur is more like 700K not 10-15K.

Dieser Beitrag wurde bereits 2 mal editiert, zuletzt von »Diago« (21. April 2020, 19:15)

I did the math right now on a piece of paper, i studied it and i scored top of my class in "heat transfer" class. You can trust a german engineer when he tells you: Yes there is a difference with an increased flow, no it does not dramatically change UNLESS you change the form of the flow from laminar to turbulent and thus reducing the boundary layer (https://en.wikipedia.org/wiki/Boundary_layer). All my calculations (though pretty simplified because there are a huge number of variables) show pretty the same: Unless you are in some real edge cases design wise (which i hardly doubt in watercooling) the flow stays the same wether you have 60L/h or 300L/h.Adding to this:Alrighty.

I did some follow up testing with the system assembled and running, and I believe I have confirmed that it is the flowmeter readout that is incorrect, not the actual flow that is diminished.

I loaded up the system with a loop of heaven benchmark at 4k, maximum quality settings, vsync off, on a highly overclocked Pascal Titan X and let it run until the system reached a steady state.

The system was maintaining a temperature delta between the measured coolant temperature at the GPU and the core temperature of the GPU of only between 2 and 4C. If the flow meter readouts were accurate, this should not be possible.

Does anyone have any flowmeter troubleshooting suggestions? Can they be opened up and maintained?

Thanks,

Matt

Yes it can be opened and maintained.

As i said before: Its more than unlikely that the sensor itself has a problem. If there would be a problem normally it wouldn´t show any value at all because there is only one moveable piece in it. If that would be stopped or blocked because some particle in the water it would show nothing.. a partcle that just slows it down (and sticks to it) would be very hard to find.

The Temperature Delta is in no way a source of reading your flow. The difference from 50L/h to 250L/h is maybe 2-3K. Only if your flow is less then 40L/h you will see a real effect by enhancing the flow. Effects above that could be easily bee within the error margin of the temperature sensors.

As to the point of viscosity:

10% could make a huge differance.

This does not jive with the data I have seen on the subject, or the "rule of thumb" guides on any of the enthusiast water cooling sites out there.

Maybe this is accurate for very low heat systems, but 40 L/H is a laughably inadequate flow rate for an enthusiast system where each block (GPU & CPU) could be dissipating 300W to 350W of heat.

My Pascal Titan X, fully overclocked puts out ~310W at full load. My Threadripper 3960x at full load can get up to 320W at full load.

The rule of thumb in all enthusiast water cooling forums is to target 1 GPM, (~227 L/H), as that is an approximate point where diminishing returns set in to the point where further flow increases may not be worth it. Still, measurable improvements are notable up to about 1.5GPM (340 L/h) after which thermal probe accuracy starts to limit the ability to distinguish probe error and actual temperature improvement.

While the rule of thumb target is ~ 1 GPM (227L/H) generally it is conceded that if you can reach a minimum of 0.8 GPM (~180L/h) you are OK. Not great, but OK.

Usually, unless a loop is large and complex, a single D5 pump running at 100% speed is sufficient to reach ~ 0.8 to 1.1 GPM (180 to 250 L/H)

40 L/H is ~ 0.17 GPM. That might be fine for idle flow rates if you have a PWM pump and can dial it down when temps are low, but for load conditions it is a joke.

For some historical reference.

My old loop ( single D5 pump, EK Fullcover Block for Pascal Titan X, EK Supremacy EVO Block for CPU, 1x 420mm 45mm thick Alphacool Radiator, 1x 280mm "Monsta" 84.5mm thick radiator) achieved about 0.9 GPM (~205 L/H) at full pump speed with EK Cryofuel Coolant

When I upgraded to Threadripper, at first I used the same loop, just replacing the CPU block with a Watercool Heatkiller IV Pro Threadripper block. It was apparently less restrictive than the EK Supremancy EVO, because this change alone increased max flow to 1.1GPM (~250L/h) with EK Cryofuel Coolant

When I embarked on a larger loop for my threadripper with a little bit of an unusual parallel flow radiator routing (see here) I decided to add a second pump to help overcome what I thought would be a more restrictive loop. Initial testing with just distilled water showed a single D5 pump at full speed resulting in 1.1 GPM (~250L/H), and with both pumps up to 1.6 GPM (~360 L/H)

This is why this drop is so puzzling.

Just try it yourself. Switch one pump off (if your flow stays above 40-50 L/h) you will not see a huge difference (like 10K+) in temperatures. For that you need to wait to the point where the water temperature does not change anymore and your system becomes static.

This is somehow a intercontinental difference - you americans tend to always go for high flow, europeans tend to go for sufficient flow but as silent as possible. At least here on the europe side there is a large community who does really good test nearly scientifically based around all aspects. All found that Flow CAN improve your temperatures but only by a margin that is not big enough to bother. Better get another radiator and lower the watertemp from the start.

Edit:

The above is only true for watercooling PCs - if you are trying to cool down steel beams or rolling mills in steel plants its a whole different story because your delta Temperatur is more like 700K not 10-15K.

I'm an engineer myself, though fluid dynamics was never in my field.

I do trust your calculations, but I also caution against relying too much on theory. Its a great place to get started absent practical real life testing, but there are almost always factors outside of the basic theory which have an impact.

I remember back 20 years ago when Pro/ENGINEER and Pro/MECHANICA were the latest and greatest thing. We had been running some finite element analysis testing on some designs, but the results just did not look right, so for fun, I modeled a simple beam and ran finite element analysis on it, and compared it with the simple beam theory formulas. The results were off by almost an order of magnitude.

In my experience in developing and validating medical devices to ISO 13485 and FDA Part 820 requirements, theory is a great way to get started in early stage design and development, but is really only valuable up until you get your first test sample, then all bets are off. Practical results beat theory every time.

There are some fields in which relying on theory is unavoidable. For instance, Civil engineers aren't about to build a test bridge before the real thing, but that's why they tend to use such large safety margins!

I have repeatedly seen charts showing significant temperature changes up to and above the magic 227 L/H line. Maybe the difference here is what we are considering significant. When a single degree C can be the difference between maintaining dynamic boost clocks, and a lower clock, every degree counts. And if I can justify running a loop at a 1C higher temp because my relatively quiet pumps are maintaining higher flow, so I have a lower delta T, and thus can spin my fans more quietly, that is a win win win.

Running a D5 pump at 40% vs 100% has a practically insignificant difference in noise level, as long as the pump is properly dampened. If that extra pump pressure which costs me close to nothing in noise can get me a lower Delta T between loop and core temp, I can run my fans much much slower. A 1C difference can have a large impact on fan noise, especially as your loop temp gets closer to ambient.

And maybe this is another difference between usage conditions.

For instance, I find that my GPU performs best if I keep it below 40C core temp during max load. I'm still working out what this means for where I need to maintain my loop temp in this loop, but in my last one this meant a loop temp of 32C or below. Now if you factor in summer time ambient temperatures of 25C, that doesn't leave much space for a temperature delta to ambient. Not difficult to achieve if you don't mind loud fan noise, but if you'd like to do it quietly, every degree counts! If added flow helps even 1C, that's 1/8th of my loop to ambient delta T!

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »mattlach« (21. April 2020, 21:12)

Anyway,

This is all mostly irrelevant to the issue at hand.

Martin's Flow Rate Estimator is very old at this point, and lacks modern parts, but modelling my loop with similar parts it predicts approximately 1GPM with one D5, and 1.5GPM with two D5's.

This mostly lines up with my previous measurements.

Nothing has changed in the loop since then, performance seems equivalent to where it was before, both subjective (from observing reservoir during fill) and objective (though not perfect as Diago has pointed out) temperature performance measurements.

The Aquaero has been eliminated as a cause by testing with another Aquaero and getting the same results.

Thus all clues point towards a mystery problem with the flowmeter.

I can't take it apart right now to check it, as we are self isolating due to the COVID19 virus due to having high risk individuals in our household. I just barely have enough coolant to fill the loop right now, and cant afford any losses by draining and filling, or I won't be able to get more until after self isolation is over. (I have plenty of coolant concentrate, but I am completely out of distilled water. It's cheap at the store (~$1 per gallon), but I refuse to pay the ridiculous prices they are charging on Amazon for delivery (~$20 per gallon) on principle)

So, since temps are good in my tests, all evidence is pointing towards the flowmeter and not an actual flow problem, I'm probably going to live with it for now until this pandemic is over, and then figure out what to do about it.

In the mean time, are there any electrical tests I can do with my multimeter to diagnose if everything is electrically OK with the flow meter?

My understanding is it works a little bit like how a fan RPM signal works, except it is supplied with 5v instead of 12v? Does it just take 5v on one wire (with ground on another) and then returns two signals per revolution back to the Aquaero which handles all calibration? I'd appreciate any suggestions here.

Thank you all for your input.

This is all mostly irrelevant to the issue at hand.

Martin's Flow Rate Estimator is very old at this point, and lacks modern parts, but modelling my loop with similar parts it predicts approximately 1GPM with one D5, and 1.5GPM with two D5's.

This mostly lines up with my previous measurements.

Nothing has changed in the loop since then, performance seems equivalent to where it was before, both subjective (from observing reservoir during fill) and objective (though not perfect as Diago has pointed out) temperature performance measurements.

The Aquaero has been eliminated as a cause by testing with another Aquaero and getting the same results.

Thus all clues point towards a mystery problem with the flowmeter.

I can't take it apart right now to check it, as we are self isolating due to the COVID19 virus due to having high risk individuals in our household. I just barely have enough coolant to fill the loop right now, and cant afford any losses by draining and filling, or I won't be able to get more until after self isolation is over. (I have plenty of coolant concentrate, but I am completely out of distilled water. It's cheap at the store (~$1 per gallon), but I refuse to pay the ridiculous prices they are charging on Amazon for delivery (~$20 per gallon) on principle)

So, since temps are good in my tests, all evidence is pointing towards the flowmeter and not an actual flow problem, I'm probably going to live with it for now until this pandemic is over, and then figure out what to do about it.

In the mean time, are there any electrical tests I can do with my multimeter to diagnose if everything is electrically OK with the flow meter?

My understanding is it works a little bit like how a fan RPM signal works, except it is supplied with 5v instead of 12v? Does it just take 5v on one wire (with ground on another) and then returns two signals per revolution back to the Aquaero which handles all calibration? I'd appreciate any suggestions here.

Thank you all for your input.

Dieser Beitrag wurde bereits 2 mal editiert, zuletzt von »mattlach« (21. April 2020, 21:01)

Yea I realize that but when I see people posting up their pictures on Social Media of their Builds showing a Barrow Flow meter on a Single D5 showing 6.5lpm(390lph) I always have to have a nice Chuckle.I always question people’s flow numbers, I’m running triple D5 pumps in series and using a AQ high flow sensor and with all 3 at max only see 400lph.

Added pumps in series increase head pressure linearly, but flow rate does not increase linearly with head pressure.

This helps explain it. Each pump added to a loop results in less of a gain in flow than the pump before it, and how much depends on the system curve of the loop.

I'd suggest you to open it up and clean it. There is not much you can do wrong. It just 4 screws to remove the top plate and then another 3 screws to remove the sensor housing. Then you can take out the impeller and clean/check it.

Or maybe you have some blockage in one of your blocks that drops the flow?

Or maybe you have some blockage in one of your blocks that drops the flow?

The barrow Flow meter is not worth a penny. Its gives you WAY to much values... i posted the link from igors Lab in a previous post (still german).Yea I realize that but when I see people posting up their pictures on Social Media of their Builds showing a Barrow Flow meter on a Single D5 showing 6.5lpm(390lph) I always have to have a nice Chuckle.I always question people’s flow numbers, I’m running triple D5 pumps in series and using a AQ high flow sensor and with all 3 at max only see 400lph.

Added pumps in series increase head pressure linearly, but flow rate does not increase linearly with head pressure.

This helps explain it. Each pump added to a loop results in less of a gain in flow than the pump before it, and how much depends on the system curve of the loop.

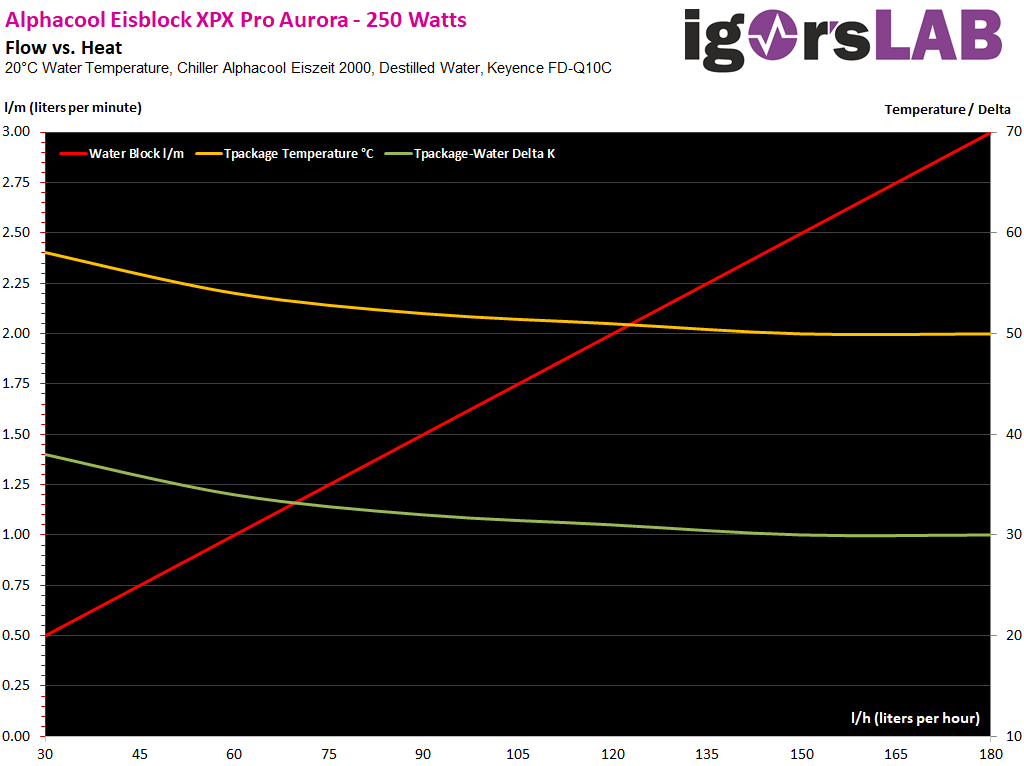

I found another just recently published test, from Flow vs Temperature

NOTE: this is for one specific CPU Block, the GPU Block he has tested performs better with higher flow rate. As i said before it is highly depending on the Design. the more complex the design is the more it seems to profit from higher flows. I suspect you can minimise "deadzones" in the current with higher flow. But the temperatures tend to got towards an extrem value, so you need to make a decision wether to increase the flow is worth it any more.

To be fair i stand corrected anyways as it seems that there can be a significant influence of the flow on the temperature.

Back to the sensor (aka on topic):

Here is a picture from the inside of it:

Yea I realize that but when I see people posting up their pictures on Social Media of their Builds showing a Barrow Flow meter on a Single D5 showing 6.5lpm(390lph) I always have to have a nice Chuckle.I always question people’s flow numbers, I’m running triple D5 pumps in series and using a AQ high flow sensor and with all 3 at max only see 400lph.

Added pumps in series increase head pressure linearly, but flow rate does not increase linearly with head pressure.

This helps explain it. Each pump added to a loop results in less of a gain in flow than the pump before it, and how much depends on the system curve of the loop.

I've never seen this, but yes, that would make me chuckle too. Unless they are just driving a round loop of tubing with nothing in it :p

The value of calibration! :p

Yea I realize that but when I see people posting up their pictures on Social Media of their Builds showing a Barrow Flow meter on a Single D5 showing 6.5lpm(390lph) I always have to have a nice Chuckle.I always question people’s flow numbers, I’m running triple D5 pumps in series and using a AQ high flow sensor and with all 3 at max only see 400lph.

Added pumps in series increase head pressure linearly, but flow rate does not increase linearly with head pressure.

This helps explain it. Each pump added to a loop results in less of a gain in flow than the pump before it, and how much depends on the system curve of the loop.

I've never seen this, but yes, that would make me chuckle too. Unless they are just driving a round loop of tubing with nothing in it :p

The value of calibration! :p

Diago,

As an aside, I just realized what may have been a contributing factor in our disagreement earlier.

I don't think we were talking about the same Delta T.

In retrospect I think you were calculating the temperature of the coolant before and after the block. Is that correct?

The Delta T I was talking about was the temperature difference between the coolant temperature, and the actual silicon core temperature as measured on die.

This is much too complex of a relationship (IMHO) to accurately calculate in theory, as it depends on too many unknowns. Some things we know (coefficient of heat conductance of copper, for instance) but then there are other aspects as well. How flat is the block? How flat is the top of the heatspreader of the chip? What thermal paste is being used? How thick is it in its final mount? What does the chip assembly look like underneath the heat spreader? what is the exact heat dissipation, etc. etc. etc.

I tend to think of water cooling loops from the perspective of two distinct Delta T's.

Ambient Air <---- DT1 ----> Coolant Temp <---- DT2 ----> Die temp.

DT1 depends on a combination of heat load, flow rate, radiator capacity/efficiency and fan speed.

DT2 depends almost exclusively on heat load, block efficiency and flow rate. Since I know I was running the same silicon at the same settings and voltages, I knew that the heat load was the same as before, and the block was the same as before, thus the only variable here is the flow rate, and I feel fairly confident that I can tell the difference in flow rate up based on this delta T value.

This is also why I am a proponent of high flow rates. If I can minimize DT2, I can allow my coolant temp to be higher, and thus lower my fan speeds making everything quieter. a difference of 1C can mean the difference between deafening fans and relative quiet, especially since DT1 heat transfer is more efficient as the DT increases.

In my ideal water loop, the flow rate is high enough where you hvae a perfect steady state, and cannot measure a difference in coolant temp between any two points in the loop. The coolant is passing through so fast that you hvae a complete steady state.

Diago,

As an aside, I just realized what may have been a contributing factor in our disagreement earlier.

I don't think we were talking about the same Delta T.

In retrospect I think you were calculating the temperature of the coolant before and after the block. Is that correct?

The Delta T I was talking about was the temperature difference between the coolant temperature, and the actual silicon core temperature as measured on die.

This is much too complex of a relationship (IMHO) to accurately calculate in theory, as it depends on too many unknowns. Some things we know (coefficient of heat conductance of copper, for instance) but then there are other aspects as well. How flat is the block? How flat is the top of the heatspreader of the chip? What thermal paste is being used? How thick is it in its final mount? What does the chip assembly look like underneath the heat spreader? what is the exact heat dissipation, etc. etc. etc.

I tend to think of water cooling loops from the perspective of two distinct Delta T's.

Ambient Air <---- DT1 ----> Coolant Temp <---- DT2 ----> Die temp.

DT1 depends on a combination of heat load, flow rate, radiator capacity/efficiency and fan speed.

DT2 depends almost exclusively on heat load, block efficiency and flow rate. Since I know I was running the same silicon at the same settings and voltages, I knew that the heat load was the same as before, and the block was the same as before, thus the only variable here is the flow rate, and I feel fairly confident that I can tell the difference in flow rate up based on this delta T value.

This is also why I am a proponent of high flow rates. If I can minimize DT2, I can allow my coolant temp to be higher, and thus lower my fan speeds making everything quieter. a difference of 1C can mean the difference between deafening fans and relative quiet, especially since DT1 heat transfer is more efficient as the DT increases.

In my ideal water loop, the flow rate is high enough where you hvae a perfect steady state, and cannot measure a difference in coolant temp between any two points in the loop. The coolant is passing through so fast that you hvae a complete steady state.

No we were talking about the same Delta T, but i wasn´t specifically talking about the delta T because its just a relative number. For PC Cooling the absolute number should be more important - thats the CPU/GPU Temp.

If your water has 40°C and your delta T is 5K your CPU has 45°C... if your water has only 30°C and your delta T is 10K your CPU has 40°C. That said it is more important to get your water temp down than the delta T.

It´s just a different view point - i would never use 2 pumps to get such a high flow, first because its expensive and uses more power. Second, and that is a simple truth: If your system won´t run when its 3K hotter your cooling solution is not

sufficent at all and you need to make fundamental changes to it.

To get a steady state you don´t need such a high flow. i have about 1 liter (little less) in my system that means it will be circulating about 60 times per hour.. that is pretty fast already.

btw. my delta T (CPU) is 42K right now (125W Ryzen 2700x) - GPU its 12K both at 100% Water temp is 33°C. Flow 53,7L/h

Dieser Beitrag wurde bereits 1 mal editiert, zuletzt von »Diago« (23. April 2020, 09:37)

- 1

- 2

Ähnliche Themen

-

English forum »

English forum »-

53068 Flow sensor?

(17. Februar 2019, 23:55)

53068 Flow sensor?

(17. Februar 2019, 23:55)

-

English forum »

English forum »-

Flow sensor (53068)

(9. Oktober 2016, 14:57)

Flow sensor (53068)

(9. Oktober 2016, 14:57)

-

English forum »

English forum »-

Need assistance with High Flow Meter USB Setup.

(4. August 2013, 02:52)

Need assistance with High Flow Meter USB Setup.

(4. August 2013, 02:52)

-

English forum »

English forum »-

Aquaero 5 XT and flow meters

(30. April 2011, 10:24)

Aquaero 5 XT and flow meters

(30. April 2011, 10:24)

-